금형

금형의 정의

금형, in simple terms, is a tool used to create three-dimensional objects by injecting or pouring material into a pre-designed cavity. It works by forming the desired shape with the negative space in the mold. Once the material is injected, the mold is then cooled, and the product takes the solid shape of the mold. This process is commonly referred to as “injection molding” and is one of the most popular techniques used in the manufacturing process.

금형의 역사

The use of molds can be traced back to the early civilizations of ancient Egypt, Greece, and Rome. Back then, molds were made of wax, clay, and wood and were manually crafted to form objects such as pottery and jewelry. With industrialization and technological advancements, molds have become more sophisticated and are now made of durable and robust materials such as steel, aluminum, and titanium. The process of creating molds has also improved with the integration of computer-aided design (CAD) and computer-aided manufacturing (CAM), leading to more precise and efficient molds.

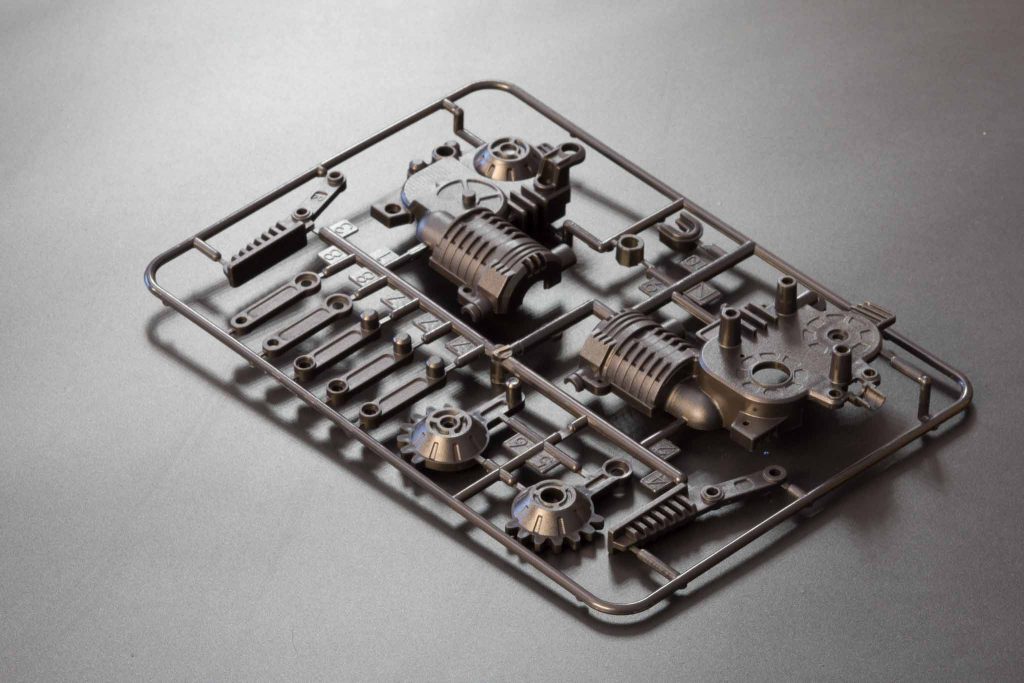

금형의 종류

There are numerous types of molds available, each used for a specific purpose depending on the material being processed and the shape and size of the desired product. Below are some of the most commonly used molds:

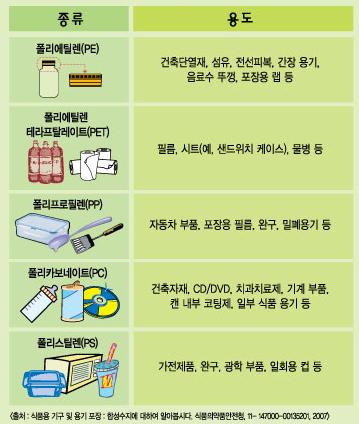

1. Injection molds – used to produce items with plastic, rubber, or other similar materials. These molds are typically made of steel, aluminum, or beryllium-copper alloy.

2. Blow molds – primarily used to create hollow objects such as bottles, containers, and tanks.

3. Hot runner molds – used in injection molding to maintain a consistent temperature within the mold.

4. Die casting molds – used to make thin-walled parts with high precision. These molds are usually made of hardened steel.

5. Compression molds – used for materials such as rubber, silicones, thermoplastics, and composite materials.

6. Rotational molds – used for making hollow objects such as toys, garbage cans, and traffic cones.

금형 제작 과정

The process of making molds involves many steps and requires detailed planning and precision. Here are the basic steps involved in making a mold:

1. Designing: The design process involves creating a digital or physical model of the desired product, which will then be used to create the mold.

2. CNC Machining: Once the design is finalized, the next step is to use CNC machines to create the mold’s outer shape.

3. Electrode Manufacturing: This process involves the creation of electrodes that will be used to form the mold’s internal shape.

4. EDM Machining: EDM or Electrical Discharge Machining is used to create the mold’s internal shape using the electrodes.

5. Assembly: The individual mold components are assembled, ensuring that they fit precisely together.

6. Inspection: The final step involves inspecting the mold for any defects or issues that may affect its performance.

금형의 유지 보수

The durability and lifespan of a mold depend on the quality of the mold material and the manufacturing process. However, proper maintenance is crucial to ensure the mold’s optimal functioning and longevity. Below are some essential tips to maintain molds:

1. Regular Cleaning: Molds should be cleaned regularly to remove excess materials that can accumulate and potentially damage the mold.

2. Lubrication: Greasing the mold can reduce friction and prolong its lifespan.

3. Inspection: Regular inspections are important to identify any issues such as cracks or defects that could cause problems in the production process.

4. Storage: Proper storage is essential to protect the mold from damage caused by environmental factors such as humidity and temperature fluctuations.

5. Repair: Any damage or wear and tear should be repaired immediately to prevent further damage and prolong the mold’s lifespan.

금형의 활용 분야

Molds are essential tools in many manufacturing industries, including the automotive, construction, aerospace, and electronic industries. Below are some of the areas where molds are commonly used:

1. Automotive Industry: Molds are used to make car parts, such as bumpers, body panels, and dashboards.

2. Construction Industry: Molds are used in the production of concrete products, including bricks, blocks, and paving stones.

3. Aerospace Industry: Molds are used to make parts for airplanes and spacecraft.

4. Electronics Industry: Molds are used to produce parts for electronic devices, such as computer components and mobile phone casings.

5. Medical Industry: Molds are used to make medical instruments, implants, and prosthetics.

FAQs

Q: What materials are commonly used to make molds?

A: The most commonly used materials for molds include steel, aluminum, beryllium-copper alloy, and titanium.

Q: Can molds be recycled?

A: Yes, molds can be recycled. Scrap molds made of metal are typically melted down and reused.

Q: What is the lifespan of a mold?

A: The lifespan of a mold depends on the quality of the mold material and the manufacturing process. With proper maintenance and care, molds can last up to decades.

Q: What is the difference between injection molds and blow molds?

A: Injection molds are used to produce solid objects, while blow molds are used to produce hollow objects such as bottles and containers.

Q: Can molds be repaired?

A: Yes, molds can be repaired. Any damage or wear and tear should be repaired immediately to prevent further damage and prolong the mold’s lifespan.

Conclusion

In summary, molds or 금형 are valuable tools used in manufacturing industries to create objects with precision and accuracy. Over time, the materials and techniques used to create molds have improved leading to more efficient and high-performance molds. With proper maintenance and care, molds can last for decades while continuing to produce high-quality products.

사용자가 검색한 키워드: 금형

Categories: Top 55 금형

금형의 모든 것 [세상의모든지식 X 챔프]

여기에서 자세히 보기: g3magazine.com

주제와 관련된 이미지 금형

![금형의 모든 것 [세상의모든지식 X 챔프] 금형의 모든 것 [세상의모든지식 X 챔프]](https://g3magazine.com/wp-content/uploads/2023/06/hqdefault-68.jpg)

금형 주제와 관련된 이미지 29개를 찾았습니다.

![금형] 금형의 종류 ( Press Die, Injection Mold, Die Casting Mold 등) 금형] 금형의 종류 ( Press Die, Injection Mold, Die Casting Mold 등)](https://blog.kakaocdn.net/dn/cVCHzs/btquKIi5j3O/GAZnSzQcr2RKOckcqjPOIk/img.png)

![티어원] 비즈니스를 위한 금형사출 용어 총정리 티어원] 비즈니스를 위한 금형사출 용어 총정리](https://capa-blog-api.capa.ai/wp-content/uploads/2022/09/%EC%83%81%EC%B8%A1%EA%B3%BC-%ED%95%98%EC%B8%A1%EB%B6%80.png)

![티어원] 비즈니스를 위한 금형사출 용어 총정리 티어원] 비즈니스를 위한 금형사출 용어 총정리](https://capa-blog-api.capa.ai/wp-content/uploads/2022/09/%ED%8C%A8%EB%B0%80%EB%A6%AC-%EA%B8%88%ED%98%95%EA%B3%BC-QDM-1024x565.png)

![🔩금형기술사] 사출금형 - 금형 이해 | [금형기술사 시험 대비] 🔩금형기술사] 사출금형 - 금형 이해 | [금형기술사 시험 대비]](https://i.ytimg.com/vi/BCHYyCp3JY4/maxresdefault.jpg)

![Fish cakes could survive thanks to this technique! Let's learn about the mold [ATKITWxChamp] - YouTube Fish Cakes Could Survive Thanks To This Technique! Let'S Learn About The Mold [Atkitwxchamp] - Youtube](https://i.ytimg.com/vi/1HGjYngYnas/maxresdefault.jpg)

![금형기능사] 금형기능사]](https://i.ytimg.com/vi/jqefcV5S3tg/maxresdefault.jpg)

Article link: 금형.

주제에 대해 자세히 알아보기 금형.